LOADING 0%

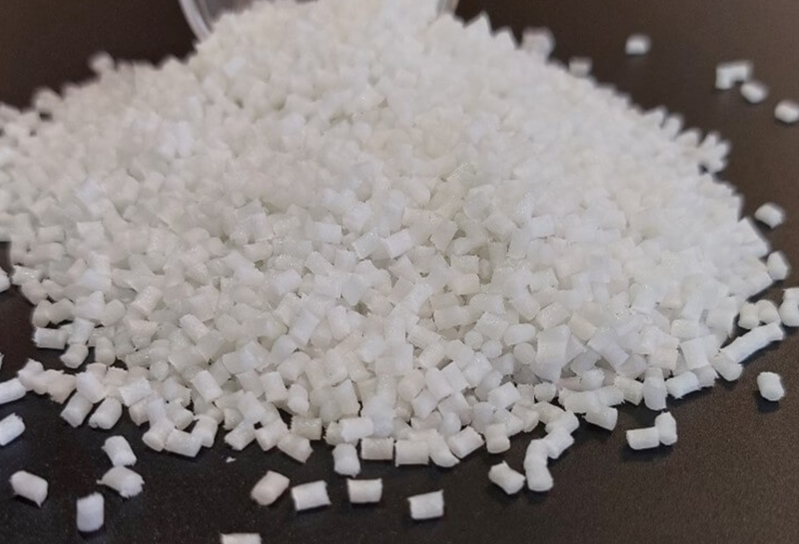

Polypropylene and Polyamide Alloy Reinforced with Glass Fibers – Superior Dyeability and Mechanical Performance

Polypropylene, while versatile, often faces challenges with coatings and adhesives due to its low surface energy, making it difficult to dye or bond. To address this, polypropylene is combined with polyamide, a polymer known for its excellent mechanical properties and dyeability. The addition of glass fibers further enhances the interface between these two immiscible polymers, creating a high-performance material with exceptional properties.

Key Advantages of Polypropylene/Polyamide/Glass Fiber Compounds:

Applications of Polypropylene/Polyamide/Glass Fiber Compounds:

This advanced material is ideal for use in automotive components, industrial parts, and applications requiring multiple performance attributes. Its unique combination of dyeability, mechanical strength, and wear resistance makes it a preferred choice for demanding environments.

Why Choose Polypropylene/Polyamide/Glass Fiber Alloy?

By combining polypropylene, polyamide, and glass fibers, manufacturers can achieve a material that overcomes the limitations of traditional polypropylene while offering enhanced dyeability, mechanical performance, and durability. Discover how this innovative alloy can elevate your product design and functionality.